Crosscall is a brand name that many smartphone users, especially those living outside Europe, won’t be too familiar with. The French manufacturer specializes in rugged devices and mainly caters to outdoor sports and business users. We caught up with Crosscall product manager Christophe Martin to find out more about the company, Crosscall users, and the technologies used in rugged devices. [Note: This interview has been edited for clarity.]

What is your role at Crosscall?

I am a product manager and in charge of smartphone development and conception. I am also involved in camera research and development, including technology sourcing, and closely follow the technological developments in the camera area.

Can you tell us little bit more about Crosscall?

Crosscall is a French company, with all our capital in France. It is just over 10 years old and was founded by Cyril Vidal. Cyril comes from the construction industry but also has a passion for water sports, especially jet skis. So he had specific requirements in both his professional and personal life for a waterproof and robust device with good battery life that could also perform well in daily life — for example, when taking and sharing pictures.

We currently have 140 employees in France and our focus is on building waterproof, durable, and autonomous products. The company is growing quickly, with a turnover of 71.6 million Euros last year and an estimated 89 million Euros this year. We have more than 20,000 points of sale and are also growing in the B2B sector. We have contracts with major companies and organizations in France — for example, SNCF (the French national railway), public entities, and the army.

We also have a team in Hong Kong who maintains our relationship with the factories in China. The Hong Kong team takes over once the product has been conceived and the budgets have been approved.

France is currently our key market. Here our devices are available through a number of channels and carriers but also through some specialty shops — for example, construction and sports, so we have really broad coverage. We are also planning to expand further globally. So far we are in 17 countries, mainly in Europe, but also as far away as South Africa.

Who are typical Crosscall target users?

We know our users well because we have built the company using a user-centric approach and we want to stick to this approach in the future. Crosscall has two kinds of users, professionals and sports enthusiasts, and sometimes those two groups overlap. For example, you can work in a vineyard and also be a trail runner. The environmental conditions can be very similar in terms of rain, dust, and shock.

The only way to make sure our products make sense is by being close to our users, and being in France helps with that. Several times per year we meet with groups of our sports enthusiast users from different types of sports, such as mountain biking, snowboarding, or surfing. We also meet customer groups from professional sectors.

We gather information about user requirements, which feeds into the development of new products. As soon as we have prototypes, we send them out to user groups and ask them for feedback to check if the proposition is in line with their expectations. If it is possible to do so, we implement the feedback and we repeat this process until launch of the product.

After launch, the user group members receive a production unit and again provide feedback which we will take into account for improvements to current and future products.

The Crosscall Trekker-X4 is used by employees of the French railway SNCF. Can you tell us more about this project?

From the beginning we developed strong relationships with professional users from different sectors such as transport, public safety, construction, and healthcare. All these user groups’ requirements feed into the development of any new product. In the specific case of SNCF, the company required robustness, durability, autonomy, and network stability. The latter two are especially important, as the device users are typically always moving on a train.

SNCF put this project out to tender and after in-depth testing of 5 different devices, the Trekker X-4 was selected. SNCF put a lot of emphasis on durability over a three or four year period. In the cases of some rival phones, they found that between 10 and 20 percent of the devices were returned broken, which would lead to planning insecurity and additional cost.

How the SNCF employees use the device depends on their specific role in the company. For some of them it is a mobile office — for example, for emailing. Others use them to check tickets or to enter information into reports, such as alerts or specific issues.

Do the camera and audio requirements of Crosscall users differ from those of users of more conventional smartphones?

Our Core range, for example, is targeted at professional users. The user profiles for this product include construction managers or army squad leaders. These kinds of users have very specific needs in terms of reliability of the device. They want to be able to capture images in any environment, under water, in dusty conditions, or when it’s cold and snowing. Therefore the entire product has to be designed to work in such adverse conditions, because if it isn’t, you won’t be able to take a picture at all.

As far as specific camera requirements go, responsiveness is a key priority, as well as the ability to capture bright images in all light conditions. To address responsiveness, we have implemented a physical shutter button, which is easy to trigger in all conditions, even when wearing gloves. We are also making sure the autofocus is fast and accurate, allowing for image capture without delay.

For other users — for example, a police officer on an observation mission — the camera has to be discreet and needs to be capable of capturing good image quality without using the flash. So the sensor needs to be sensitive. In this kind of situation it is also very important to capture the image very quickly, as you cannot miss a decisive moment.

In other cases the camera might not be used for image capture at all, but for barcode scanning or similar applications, so again, autofocus speed and accuracy as well as the ability to record a bright image are important.

Most professional users rely more on photo capture than video, but the need for video is increasing, especially in the area of public safety. In the Crosscall lineup, the Trekker series, which is targeted at athletes and outdoor use, comes with more video features — for example, an action cam and video editing app.

Our users also have some specific audio-related requirements. In some use cases, the Core-X4 is used as a walkie-talkie replacement. Loudness of the speakers is therefore important and the device also comes with a dedicated push-to-talk button.

How do Crosscall devices differ from more conventional models in terms of ruggedness and durability?

For us, the product should last a long time and work reliably during that time. This means we put a lot effort into developing a small number of new products each year and making sure we maintain and update them over time. The new Core series products we launched in 2020 are a good example. They come with a three-year warranty to emphasize reliability and durability.

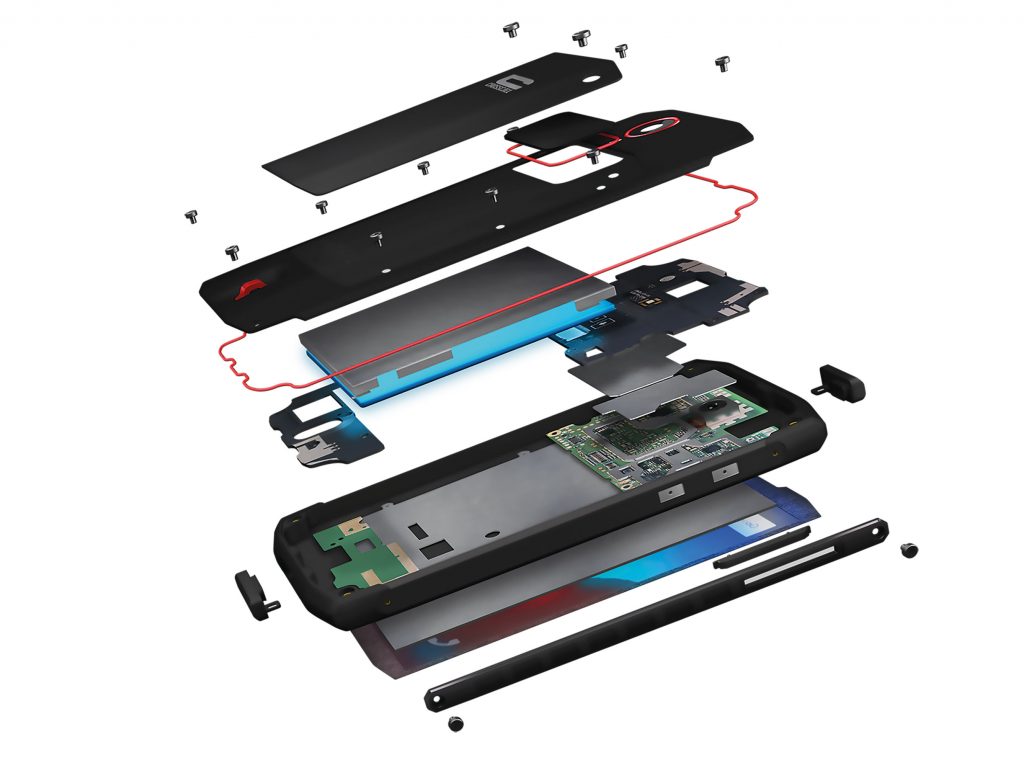

In terms of hardware, we use a mechanical approach to development in order to make the device waterproof and resistant to environmental impacts. We use specific materials and a shock-absorbent shell, so the device can pass a drop test. A lot of smartphone accidents involve broken displays. Therefore the display glass of our devices is 60 percent thicker than standard Gorilla glass, and the battery is embedded in a protective case. This ensures that no perforation occurs in case of an impact, as this could result in ignition.

Crosscall devices are designed to withstand a drop from 2 meters, which is quite a challenge. All internal components have to be designed and assembled in a specific way so they do not break when the device is dropped. The outer shell has to use materials that can absorb shock and resist flex at the same time.

The devices can also operate in a temperate range from minus 40 to plus 60 degrees Celsius (-40°F to 140°F). Our devices are used by mountain rescue in the French Alps who can face temperatures of minus 20 Celsius (-4°F). These users need to be able to make a call and maybe also take pictures in these situations. A conventional device would just freeze.

What does the rugged design mean for the design of the camera and audio components?

When selecting components for our devices, we pay a lot of attention to the temperature range they can operate in and to the overall quality, so they match our criteria for durability and longevity. The processor of the device is a key component in this respect and we are working with Qualcomm within their Extended Life program, selecting processors that allow us to maintain the software over time and make the product last longer than 3 years.

In terms of the camera, we need to make sure the lens passes internal standards related to vibration and drops, because when things break in a lens you might not be able to focus anymore. From the outside the lens is protected with a resistant type of glass.

In terms of audio, the challenge lies in making sure the device is waterproof and lets sound pass at the same time. We use a particular membrane to make sure the audio components of the device — microphone, earphones, speakers — are water- and dust-proof, but that air and sounds still can pass.

Does the rugged design create any particular challenges during manufacturing?

We have specific manufacturing requirements and our quality control process is quite rigorous. We use components that other manufacturers would not typically use. For example, in the middle of the smartphone body we insert a magnesium sheet. For this kind of component we need to find specific suppliers that are not necessarily known in the mobile industry.

During assembly and production our Hong Kong team ensures quality assessment and control, making sure that all production batches meet our internal standards and the quality we aim to deliver. These steps add to production cost and time compared to the manufacturing of more conventional devices.

Does the rugged design have an impact on the repairability of the devices?

We use the same durability and longevity approach for repairability as we do for design and manufacturing. For example, our mechanical engineers try and avoid the use of glue whenever possible to make it easier to disassemble a device to replace broken components. The Core X-4, for example, has screws on the back which when removed, allow for full access to the internal components of the device.

Easy repairability is a requirement from our professional “fleet” users, but also means our after-sales team has the option to repair in the case of warranty claims rather than send out a new device.

Where do you see areas for growth?

From the launch of the company we have specialized in the outdoor market, and we claim we created that segment. In the consumer market, we work a lot with action sports athletes, but we also see some leisure athletes who like our products. So there is an area for growth.

On the professional side of things, there are opportunities to grow by expanding from traditional sectors like construction to sectors that operate in less “hostile” conditions but still require reliability and robustness. SNCF is an example of that.

So it is important to be pretty open-minded and not limit ourselves to the market for rugged devices. We are looking at what users are doing and what kinds of devices they need and will react accordingly.

Thank you for taking the time to talk to us!

DXOMARK encourages its readers to share comments on the articles. To read or post comments, Disqus cookies are required. Change your Cookies Preferences and read more about our Comment Policy.